Here’s how this usually works: I pick a topic I think is interesting, I do my research, and then the article just kinda writes itself. Easy peasy. But every once in a while I get to the writing stage and it just doesn’t want to come. I can’t find the hook. This, friends, is one of those topics. And after having let it sit for a while I still got nothing. I don’t wanna forget everything I learned though, so I’m just gonna have to power my way through it.

And it’s not like a super technical or complicated topic—like conversion varnish, the other topic currently sitting in the “I have no idea how to write this up” file. It’s just triangle inlays! I mean, yeah, they’re one of THE defining cosmetic traits of Rickenbacker “Deluxe” guitars, but I just can’t figure out where to start.

Look, I have a great explanatory quote from John Hall explaining “why” triangle inlays that I know is part of how I should start:

“This is an old German design, favored by many of the Mittenwald School luthiers, such as Roger Rossmiesl. Actually, the original inlay was a square, halved diagnally, one side white, the other black. The black tended to visually blend into the fingerboard, so at some point only the white section was retained. You can see this first used on our acoustics guitar of 1953 and 1954 as individually hand-made by Roger.”

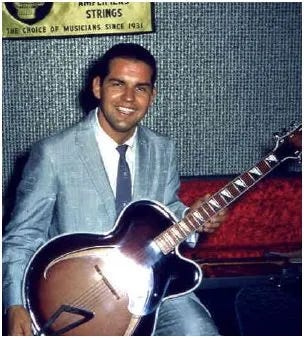

And I’ve got a picture of Rossmeisl himself holding one of those guitars to go with that quote, the oft-discussed 1957 390 (John may have his dates wrong as I’ve never seen one of these supposed ‘53/‘54 acoustics, but ‘57/‘58 examples are well documented):

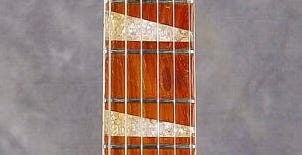

And I even have up close pictures of those black-and-white triangle inlays from a similar guitar made a year later, in 1958.

So we know the why: they come from the Mittenwald School via Roger Rossmeisl. Makes sense. And I guess F.C. Hall must have thought they looked pretty good, because when the Capri line launched in 1958 the Deluxe models all featured triangle inlays—but John was right about the black triangles kinda disappearing, so only the white triangles!

So here’s one of the points where I keep getting stuck: how did they actually make those first triangle inlays? And I get stuck here because if you know anything about 1970s Rickenbackers you already know how they did it…even if you don’t realize it. But if you DON’T know how they did it in the 1970’s then I’m spoiling THAT story by telling you how they did it in the 1950s. This whole story is SO not linear! Ah well, let’s discuss what those first triangle inlays were not. They were not crushed pearl…yet. We’ll get to that in a minute. And they were not hand cut acrylic or mother of pearl or abalone inlays like on a Gibson, although I bet you thought they might be.

But nope. They were a polyester resin, just like they would be again from the 1970s to the 2000’s. The resin was clear with a pearlescent powder mixed in. The triangle shapes were recessed into the fingerboard, those recesses were painted a light color, dams were built on the sides to hold the resin, and then it was poured in and cured in place. Because the resin shrinks slightly as it cures, the recess would be slightly overfilled and the final fingerboard radius would be sanded once the resin was dry.

Now, there is some conflicting info about the very first triangle inlays. They MAY have been cut from sheets of ground pearlescent acrylic. Or they may be as I have described. But by the end of their “original” run they were absolutely poured in place. If you have more info on this topic, please share and I will update accordingly!

There’s a great detailed description of the pouring process with photos from Paul Wilczynski on the RRF here, but here’s the highlights (these pictures are from a guitar Paul was converting from inset to full width triangles):

Folks like Paul make it look easy, but he has a lot of practice! Notice how deep that recess is and how thick the inlays are as a result. We’ll come back to that later.

Just for fun, here are some pictures Ron O’Keefe shared with me of an extremely chewed up Capri fingerboard Larry Davis replaced for him with the inlays “in” and “out” of the board. It clearly shows how thick they had to be given the board’s final radius.

And from 1957-1964, that’s how they did it. Well, mostly. You see, when the “New Capri” body shape was introduced in mid 1961–the shape we recognize today as the modern 330–the Deluxe versions (that we refer to as “OS” today) came equipped with one of the most beloved “vintage” specs—“crushed pearl” triangle inlays.

And that’s another area that’s giving me some fits: there’s conflicting info out there about the crushed pearl inlays. Let’s begin with what everyone more or less agrees on: the “crushed pearl” inlays are actually crushed mother of pearl fragments densely packed in an epoxy matrix and formed into a sheet. So far so good.

Now, where these sheets came from? This is where the stories diverge. One (probably incorrect) story is that they were…floor tiles? One story is that they were a commercially available crushed shell product similar to one available today called Abalam. And finally, a former employee has said Rickenbacker made the sheets themselves by buying crushed mother of pearl and mixing it with epoxy on large cookie sheets.

My money is on something like the “Abalam”-type sheets. That’s what most professional Rickenbacker restorers use today cause it just “looks right”.

The process of installing was slightly different than the poured inlays. 1/8” deep triangular channels were cut into the fingerboard, crushed pearl triangles were cut from WHATEVER material they actually used, the triangles were glued into place, and once the glue dried the edges were trimmed and the fingerboard and inlays were radiused.

Easy peasy. By the second half of 1962, however, for some unknown reason the New Capri/OS models had switched to the “old” poured resin inlays. Other Deluxe models made during that roughly one year period—like the F-body guitars, the 460, and the 4001–didn’t get the crushed pearl. But they would later!

Well, that’s not completely true. There’s at least one 1961 460 with crushed pearl inlays. But that guitar has other “non-production details” and may well be a prototype or custom order. Regardless, it exists, even if seems to be an outlier!

So one of the questions you see often is “if it’s a vintage reissue, why doesn’t the 360/12C63 or 360/12V64 have crushed pearl inlays?” And the simple answer is because George’s 1963 360/12 didn’t have crushed pearl inlays—it had poured resin inlays like all 1963 Deluxe guitars did.

But crushed pearl would reappear in 1964 with the launch of the “New Style”/round top 360.

Why the change? Cause they’re cool? That’s as good an answer as any, I guess! And by the middle of the year, ALL Deluxe guitars came with crushed pearl inlays.

OK, it feels like we’re about halfway done. Not gonna lie: it’s still a struggle, but let’s knock this thing out.

Crushed pearl would be the norm until 1973, when poured resin inlays would return. Why? Well, the official story (which is almost certainly at least partially responsible) is that the material used became no longer available. In this thread on the RRF, Paul Wilczynski explains that:

“Ric quit using this unique material around 1972-3 because it became unavailable. This type of shell comes from a small chain of islands near Okinawa that are now protected as a national park, hence the material is not only unavailable, but strictly protected.”

To which John Hall added:

“This is actually true. Most of that shell material came from Kohamajima Island, Okinawa, which was turned into a protected marine reserve a number of years ago. A number of years ago I visited Ishigaki Island, which is the next island over from it in the Straits of Taiwan, to see if its abundant supplies of shell material could be utilized as a replacement but there were just too many hoops to jump through on that one.”

Note that last bit. OK, sure, the original source dried up, but there’s always an alternative, right? But it probably wasn’t cheap. I mean, a 1/8” thick 5.5” x 9.5” sheet of Abalam is north of $150 today, and will only yield about 4-5 guitars’ worth of inlays. And Rickenbacker was not exactly rolling in cash in the early 1970s. Take the loss of your source, add in the cost to replace it at a time you’re not making a lot of money, apply Occam’s Razor and there you probably have it.

So they returned to the poured resin. With a couple twists. The first guitar to get the poured inlays was the 4001 in March of 1973. And they were exactly like the pre-1964 inlays.

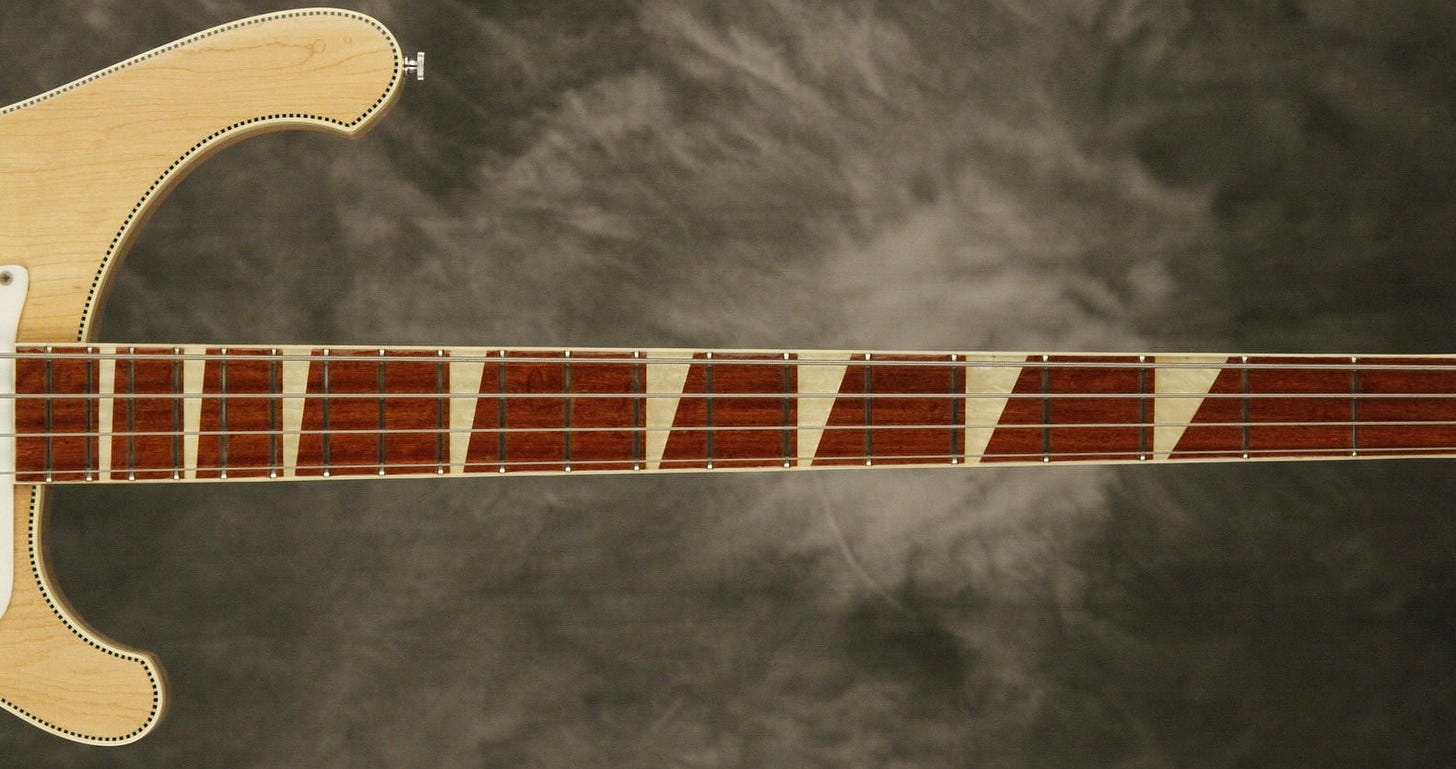

But they didn’t last long. In late April, the inlays began transtioning from full-width to inset.

Other Deluxe models would follow quickly.

As near as I can guess, somewhere towards the end of 1973/beginning of 1974 the backing paint changed from cream to light grey. This is a guess, as it’s very hard to clearly tell from the photo record. But the color DID shift slightly around this time.

So why inset instead of full width? Well, remember just how thick those poured inlays are? Scroll back up if you don’t. They’re pretty thick! The most cited reason for not making them full width is that the full width channel negatively impacted neck strength. Now you may think “you’ve got this big old beefy neck, how much strength does the fingerboard need to have?” And that’s a fair question.

The answer is “more than you think, probably”. Rickenbacker fingerboards are kinda thick compared to most other guitars. 5/16” at the crown compared to, say about 7/32” on a Les Paul or a Strat. And you’ve got TWO truss rod channels in that “big old beefy neck”. So the neck does rely some on the fingerboard for strength—more so than many other guitars.

But does that little extra sliver of wood on the edges provide THAT much more strength? Well, it certainly can’t hurt. Plus which it’s gotta be a little bit cheaper and easier to not have to dam up the edges when you pour the inlays—and you use a little less resin. So take a little more neck strength, add a little lower cost, apply Occam’s Razor and there you go.

One fun fact about the inset inlays is that they obviously had multiple templates for routing them out, and one type was a little “squarer” at the corners and one was a little “rounder”.

But over time the templates wore from use, and eventually the squarer corners disappeared.

The poured inset inlays had a good long run. And while the exact formula/materials/process changed a couple times over that run (John Hall cites 1984 and 1990), the basic appearance didn’t. Yes, color and pearlescence varied over time, depending on how much pearlescent powder was added to the resin, pour patterns, post-pour swirling, formula changes, etc. But the overall look was consistent.

Now some models during this era got full width poured inlays, like some of the Signature Limited Edition guitars—even the ones that were meant to replicate specific guitars from the crushed pearl era.

The V-Series and C-Series “vintage reissue” guitars got the full width poured inlays as well—correctly, as we mentioned above on guitars like the 360/12C63 and 360/12V64, and “incorrectly” on models like the 381V69. Look—they had one inlay technology, so that’s what they used, okay?

Until 2008, that is. And then everything changed. We returned to full width inlays on everything, and we returned to inlays cut from sheet material—only this time the inlays were cut with frickin’ lasers, man! And for that we have to thank…Grover Jackson?

The California guitar business has been super incestuous since the start—remember that George Beauchamp helped form National Guitars who Adolph Rickenbacher built bodies for, and that F.C. Hall was one of the founding Fender partners—and not much has changed since then. So it should come as no surprise to learn that Captain Super Strat himself has had a long relationship with Rickenbacker. He ran the shop from 1996-1999 and helped with all the initial CNC programming, and spent a number of years in late 2000s-early 2010s as a consultant. And one of the things he was doing in his own shop that caught John Hall’s eye in 2008 was cutting inlays with a laser.

And so, starting in late January of 2008, all Deluxe models—including the 360/12C63 which had poured inlays as new—began receiving full width, frickin’ laser-cut pearlescent acrylic triangle inlays.

Well, there’s one kinda weird detour here. For the month of February 2008–and ONLY the month of February 2008–the 4003 got inset cut acrylic inlays. Weird, right?

Installation is basically the same as was the crushed pearl: 1/8” recess routed into fingerboard, triangles (frickin’ laser) cut to fit from 1/8” thick acrylic sheets and glued in place, fingerboard and inlays radiused. Boom.

And that’s where we’ve been ever since. Well…there’s a couple of exceptions, ‘cause it wouldn’t be Rickenbacker without a couple of exceptions, right? Let’s run through them.

The first is the Al Cisneros Signature Limited Edition 4003AC, which debuted in 2018 with green acrylic inlays because marijuana lol.

Now check out this FAQ from rickenbacker.com:

Q: Why don’t modern Rickenbackers have the same inlay material as they did back in the sixties?

A: The original material hasn’t been made for more than 30 years. We’ve looked at hundreds of samples of materials purported to be “just the same” but they are not.

When something comes along that looks just like the original, be assured that we’ll use it. In the meantime, we continue to search for this from every vendor we can find but to date it’s been fruitless.

That appears to be out of date, because in 2021 90th Anniversary 480XC and 4005XC featured, for the first time on any guitar since 1973, crushed pearl inlays!

Is it EXACTLY like the 1960s version? Well, no. The flakes are maybe a little bigger and the color is maybe a little browner. But it ain’t bad, and it’s a heck of a lot closer than nothing! It’s good enough that when the 4005V launched in 2024 it had the same inlays. And at least one dealer custom run (to date) has featured them.

With the 381V69 on hiatus, the 4005V is the only “vintage” instrument currently in the line from the crushed pearl era. Will these inlays be the “default” for any future V-Series guitars? Only time will tell.

Well hell, I think we made it through! Let’s just wrap it up with a quick visual summary:

And that’s all you ever wanted to know about triangle inlays. Now if I can just figure out how to make conversion varnish interesting!

I really enjoyed this one Andy!

this is one of your best articles!

Some observations:

re: "This is an old German design, favored by many of the Mittenwald School luthiers, such as Roger Rossmiesl...". Well, Rossmiesl didn't attend Mettenwald...

It would be cool to show/discuss that the initial crushed inlays that 'looked like Ibanez inlays'... IE the '61 and initial '64 inlays don't look much like those that followed at all. And that is prob proof enough that the 'sheets' or supplier of the crushed inlays changed over time, or that RIC was making the sheets; who knows... But they are distinctly different inlays.