So before we talk about the evolution of the 4003 you need to understand why it exists in the first place—why we’re not still buying brand new 4001s today. Because when you put an early 4003 beside a late 4001 you’ll be hard pressed to tell them apart.

Ok, there are a couple minor cosmetic differences we can spot that we’ll get into, but surely they don’t merit a whole new model designation, do they? No, they don’t. The important difference is under the hood, so to speak.

So without getting too technical, we need to have a brief conversation about string tension. On an archery bow, the effect of this tension is easy to see: the more you pull back the bowstring—the more tension you put on it—the more the bow bends inward in response to that tension. The same forces are in play on your guitar neck.

There are three main components that interact to create the total tension a string exerts: length, gauge, and pitch. The longer it is, the heavier it is, and the higher you tune it, the greater the tension. Make sense? So why is that important?

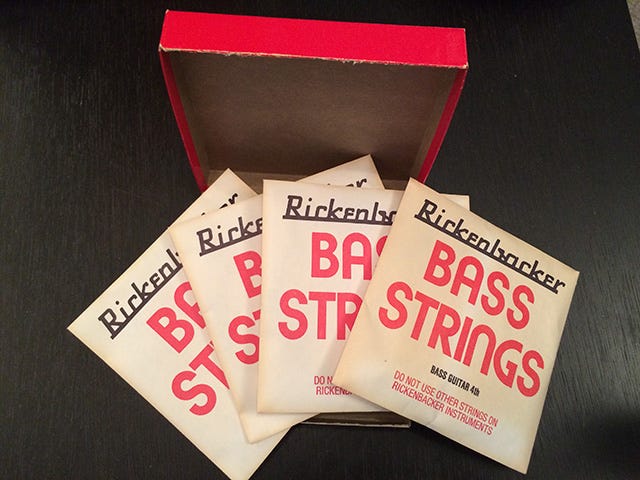

Well, the 4001’s design goes back to the late 50’s—to a time when flatwounds were the norm. And the flatwound strings of the era were of a lower tension than most modern roundwound strings. The German-made Maxima S4440 strings that were factory installed up until the end of the 4001’s run would be considered of “medium” tension. And they were really at the upper end of what the 4001 could handle.

4001s are prized today for their “thin” necks, but that thinness led to issues over time. The tension on the strings is constantly trying to turn that guitar neck into a bow. Over time some small changes were made to the 4001 to combat this. The neck pickup was moved closer to the bridge because the rout right where the through-neck met the body wings created a weak point. The truss rod access channel on the headstock was a weak point, causing string tension to pull the entire headstock “upwards”. One of the ambitions of shortening the headstock in was to reduce the overall string length, and therefore tension. The necks got a little bit thicker.

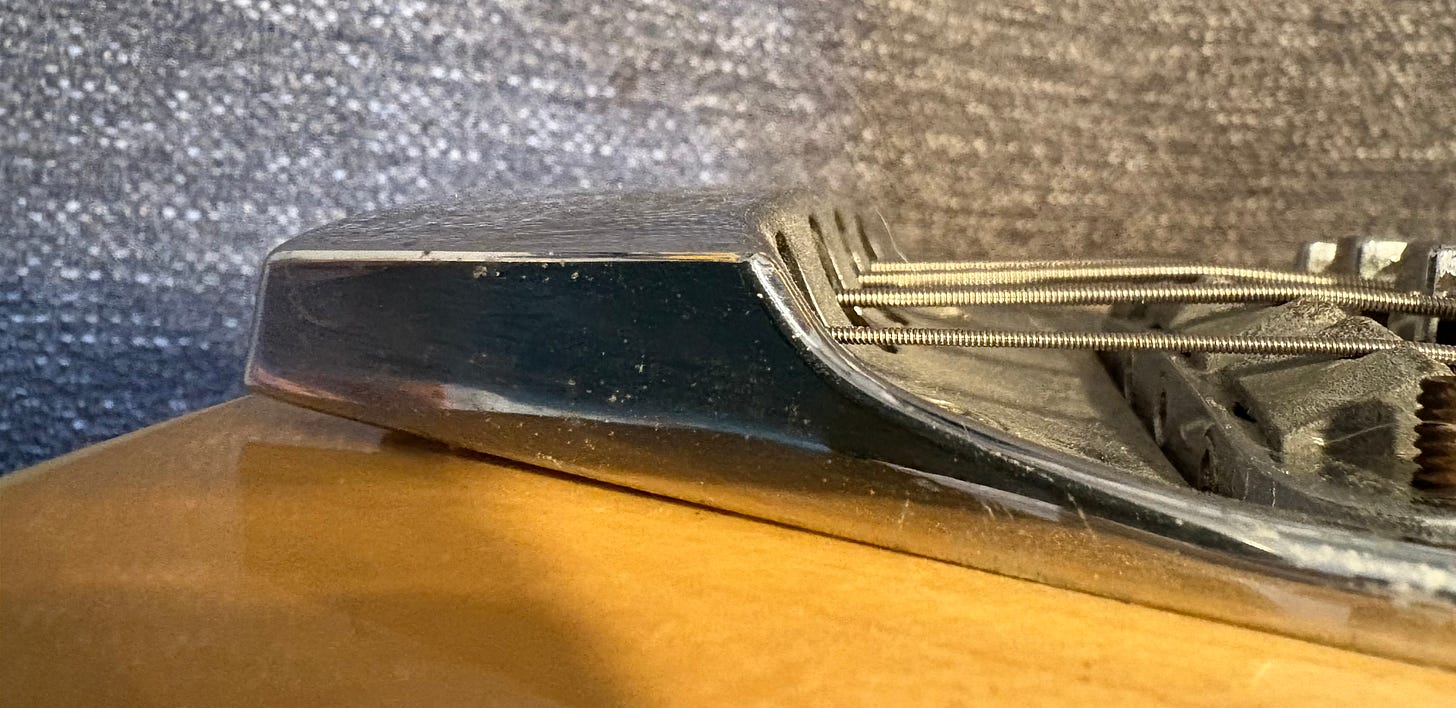

Here’s two words that tell you how much tension there is: tail lift.

As you can see, even the metal bridge is susceptible to this constant tension over time, with the tail end of it slowly being bent upwards.

Add to all of this a dual hairpin truss rod that doesn’t work the way every other truss rod system does. Try to correct a neck bow—which again, the string tension is constantly conspiring to create—the same way you would any other guitar, and you can easily pop the fretboard off.

And all of this is with those “medium tension” Maxima strings installed at the factory! But tastes changed over time and more and more players moved to heavier roundwound strings, which put still more tension on the necks and exacerbated all the issues above. So much so that the company decreed that using strings other than the factory specified Maximas would void your warranty!

So we find ourselves in a position where the market is demanding the roundwound sound, and the 4001 wasn’t really designed to handle all that tension. Enter the 4003 in 1979.

Cosmetically, same bass. Same shape, same electronics. But it came with some structural changes. Gone was the thin three piece “skunk stripe” neck, replaced by a MUCH beefier two piece neck—from a thin “D” shape to a chunky “C” shape. And the dual hairpin truss rod system was…turned around backwards so they now adjusted from the bottom of the neck instead of the top.

The bottom? Yep, the bottom. I have looked and looked to find an explanation of what they hoped this would accomplish. My best guess based on what I’ve found is that they wanted to keep the hairpin truss rod system and hoped that reorienting them would make it harder for people who didn’t understand how they work to pop the fingerboard or crack the neck. In a nod to convenience, the new 4003’s pickguard was split into two pieces to eliminate the need to remove the entire thing to adjust the truss rods.

Now, you’ll find some retconning out there—even from John Hall—that the 4003 had a completely different truss rod system from launch. That simply isn’t true. It would—but that’s a few years down the road yet.

The other change from the 4001 was to the bridge, to reduce the effect of tail lift. Did they change the metallurgy of the bridge to make it stronger? Nope. They just drilled a couple holes through that sucker so they could screw it down.

So now we know the “why” of the 4003 and the key differences between it and the 4001. While the first few prototype/preproduction guitars from 1979 may not have had all of the features listed above, by mid 1980 they had standardized as described above. So now let’s run through the evolution of the 4003 from 1980 to today.

1980

The 4003 launched alongside the 4001 as a solidbody neck-through bass with the same body/headstock shape as the period 4001, but with a thicker two piece neck with maple headstock wings and dual bottom adjusting hairpin truss rods. It featured a raised letter injection molded truss rod cover with “MADE IN U.S.A.” and “MODEL 4003” stamped at the bottom. Tuners were made by Kluson and featured black plastic bushings and mounting pads. Position marker inlays were inset poured “cure in place” triangles. Electronics were 2 black painted button-top Higains with 4 silver-top knob/1 switch mono/stereo wiring. The single level pickguard was of two parts to allow truss rod access. The bridge was a standard 4 saddle adjustable bridge with an adjustable mute and 2 additional mounting screws added to the base. Strap buttons were the standard reeded edge topped machine screws. Fun fact: the exact same screws are used on the bridge to adjust the mute!

1981

The 4003S joined the line, with all the same key features of the 4003 but with the contoured unbound body, unbound neck with dot markers, and mono wiring of the 4001S. Unlike the late 4001S, the 4003S was of neck through construction instead of set neck.

1982

Kluson, Rickenbacker’s primary supplier of both guitar and bass tuners, went out of business in late 1981. Rickenbacker bought as many Klusons as they could while they could, but had to find a replacement quickly. By mid to late 1982 the Klusons were replaced with the infamous “exploding” wavy Grover Slimlines the Klusons had themselves replaced in late 1974.

1984

There was a major change in 1984, and a LOT of minor ones. We’ll start with the minor ones.

The “vintage tone circuit” (a high pass filter capacitor) that had been standard on all Rickenbacker guitars and basses since the 1950s was removed, giving the bridge pickup a higher output with more bottom end.

The 4003FL joined the family. It was identical to a standard 4003 apart from its fretless board and dot inlays.

Around August the Kluson Slimline tuners were replaced by “Rickenbacker” branded Schaller BM tuners as part of the company’s shift to Schaller for all tuners.

During the month of November, the “MODEL 4003” imprint at the bottom of the truss rod cover disappeared. This had begun happening to other models earlier in the year, and by early 1985 all Rickenbackers wore a “generic” truss rod cover.

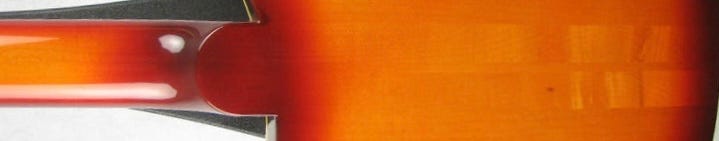

Here’s a weird one: in the month of November—and ONLY in the month of November—the neck was changed to three pieces, with a maple center “skunk stripe”. Look closely above and you’ll see it.

In December the neck was changed to one piece, which it would remain until 2009.

That covers the minor changes. Now let’s talk about the big one. But, in full candor, I’m not 100% sure that it’s a 1984 change. This change happened “sometime” between late 1984 and early 1985. It’s easy to tell which truss rod system a guitar has when you remove the truss rod cover or pickguard…but impossible to tell without. When you read up on this change, you’ll hear 1984 and 1985 discussed. Everyone is agreed that AFTER 1985 the new truss rods were in place. But as to when, exactly? We’d need to take the truss rod covers off a bunch of guitars. If someone has…please share the results!

So now the change. In John Hall’s words:

“A completely new truss rod system was designed for the 4003 (and subsequently all Ricks). While it is somewhat stronger, the main feature is adjustability and how intuitive it is. The old system was actually quite good, and I notice a number of makers now using something like our old system, but you really had to know how to make adjustments. Not doing it right damaged many otherwise perfectly good basses. The newer system allows as much as 3/8" of over- and under-bow at the 12th fret, no matter how heavy the string. Also, two new laminations with reversed back-to-back wood grain, which you cannot see in the completed bass, increase the static strength of the neck.”.

Put into layman’s terms, Rickenbacker moved from the old “hairpin” truss rods to dual “conventional” single action truss rods. The new truss rod channels were slightly curved, and the tops of the channel were filled with a wood strip (the “two new laminations”) so that the truss rods no longer came into direct contact with the underside of the fingerboard.

So still two truss rods to allow for fine tuning side to side, but now of a conventional nature and with the adjustment moved back to the headstock.

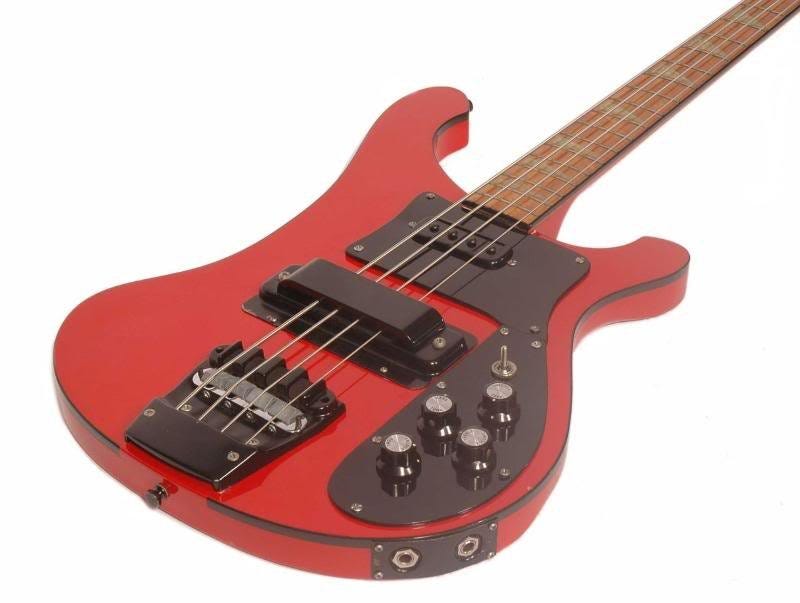

1985

While no changes were made to the 4003’s specifications, mid 1985 marked the beginning of the BH/BT (black hardware/black trim) era, with Midnight Blue, Red, White, Silver, and Mapleglo guitars equipped as standard with black finished tuners/pickup covers/bridges/strap pins/serial number plate and black plastic binding/pickguard/truss rod cover.

1986

Having been unnecessary for some period of time, the two piece pickguard was replaced by a one piece pickguard.

Two extended range 4003s were introduced this year, the first being the 5 string 4003S/5 It utilized a stock 4003S body and neck with the bass side headstock wing modified to accommodate an extra tuner. It featured a regular toaster pickup at the neck, a custom 5-polepiece Higain pickup at the bridge, a standard 4003 bridge modified to accommodate 5 strings, and Schaller M4 tuners with 3 on the bass side of the headstock and 2 on the treble side.

The second extended range 4003 was the 8 string 4003S/8.

More significant changes had to be made to the neck than on the 4005S/5 to accommodate the 8 Schaller M4 tuners, leading to an extension of the headstock—but not a change in nut width.

Like on the 4003/5 the bridge was modified to accept 8 strings.

1988/1989

At the very end of 1988 black finished bridges lost the two extra mounting screws that had been added at the 4003’s launch. Chrome bridges would lose the screws in January of 1989. A handful of the old style bridges would appear on guitars made in early 1989.

1991

In August, a new pickup bobbin appeared that was designed for use on both Higains and toasters. Its introduction ended the “fiberboard” button top Higain era for all Rickenbackers EXCEPT the 4003S/5 which would continue to use the “fiberboard” bobbin until its discontinuation in 2002.

The 4003S/8 gained a new, less modified bridge with the “teeth” reappearing over the mute.

1995

Around July, all non-vintage/reissue guitars—including the 4003–moved away from the vintage reeded edge strap button that had been used since the late 50s. It was replaced with a Schaller strap lock button, albeit still attached to the Rickenbacker style bolt instead of the “stock” wood screw. While the supplier has changed over the years, the style remains in use to this day. The reeded bolt is still used on vintage/reissue guitars, and as the mute adjustment screw on bass bridges.

1996

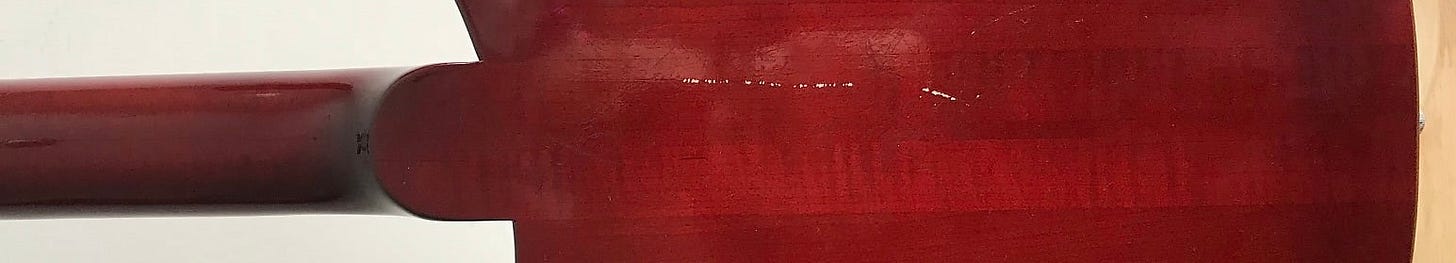

A major change occurred in December with the transition to CNC manufacturing. Prior to CNC machining, bodies and necks were hand cut using templates that wore over time, leading to slight variations from guitar to guitar and year to year as those templates wore and were replaced. Now the same shape would be cut every time. And not only was it more consistent, it was different.

By the mid 1970s, the 4001 had gotten kinda…chunky. Perhaps a planned design evolution, or perhaps a result of worn templates being used as the starting point for new templates, the body wings had over time noticeably increased in width. While that plus sizing seems to have stabilized by the late 1970’s, the same tooling/templates were used for the new 4003 when it was launched so it too was “chunky” when compared to vintage 1960s basses. But those vintage basses would be the basis for the CNC programming.

As you can see, the “horns” on the body wings slimmed down significantly, and were much more in line with the 1960s models. On the other hand, the lower body bout on the bass side got a little junk in its trunk, extending outwards about a quarter of an inch.

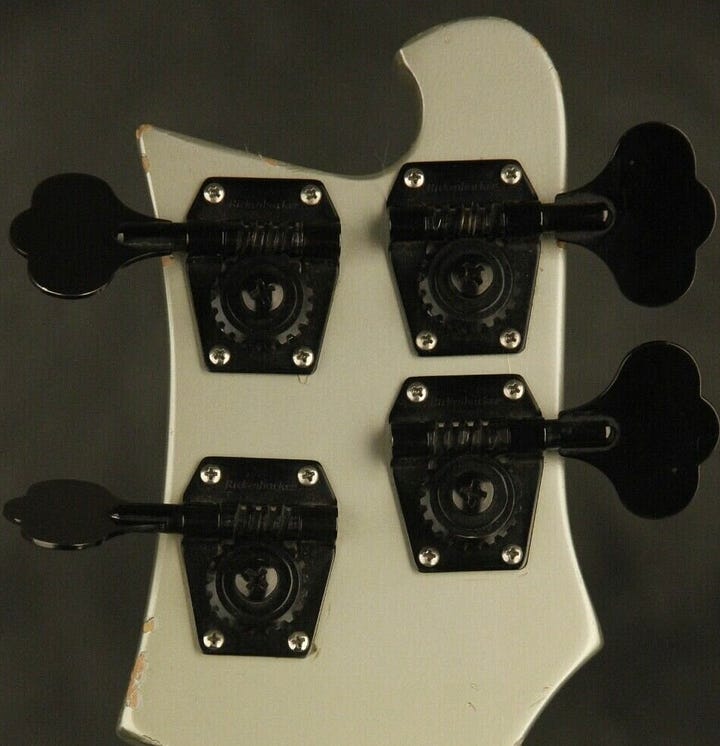

At the same time, the headstock was lengthened to closer to mid 1969-earlier lengths, most obviously spotted in the tuner spacing on the back.

While minor programming tweaks have occurred since, this is effectively the same shape being produced today.

2002

The 4003S, first generation 4003S/5, and 4003S/8 were all dropped from the pricelist. Standard production on all three ended by year end, although a handful of custom orders appear in later years.

2004

As an attempt to improve the “authenticity” of the new 325V58 launched in 2002, “dimples” were added to the corners of the toaster slots to match the injection molding marks found on pre 1963 toasters. Around November/December 2004 these bobbins began appearing on the 4003’s Higains.

2005

While the headstock length may have been returned to a closer to vintage spec in 1996, it continued to have maple wings—unlike vintage instruments. While reissue guitars like the 4001V63 received period-correct walnut headstock wings during this period, mainline production did not until October 2005 when it was made standard on all bass models.

2006

The big headline for 2006 was the introduction in January of a push pull pot that allowed players to choose between “vintage” and “standard” tones from the bridge pickup. The “vintage tone circuit” (a high pass filter) had been removed in 1984, but was reintroduced here as a player option.

Around May of 2005, the button top drive screw polepieces that had been used on Higain pickups since 1973 were replaced by adjustable polepieces on all guitars. Around May of 2006 the same happened to basses, although examples from earlier in 2006 can be found.

2008

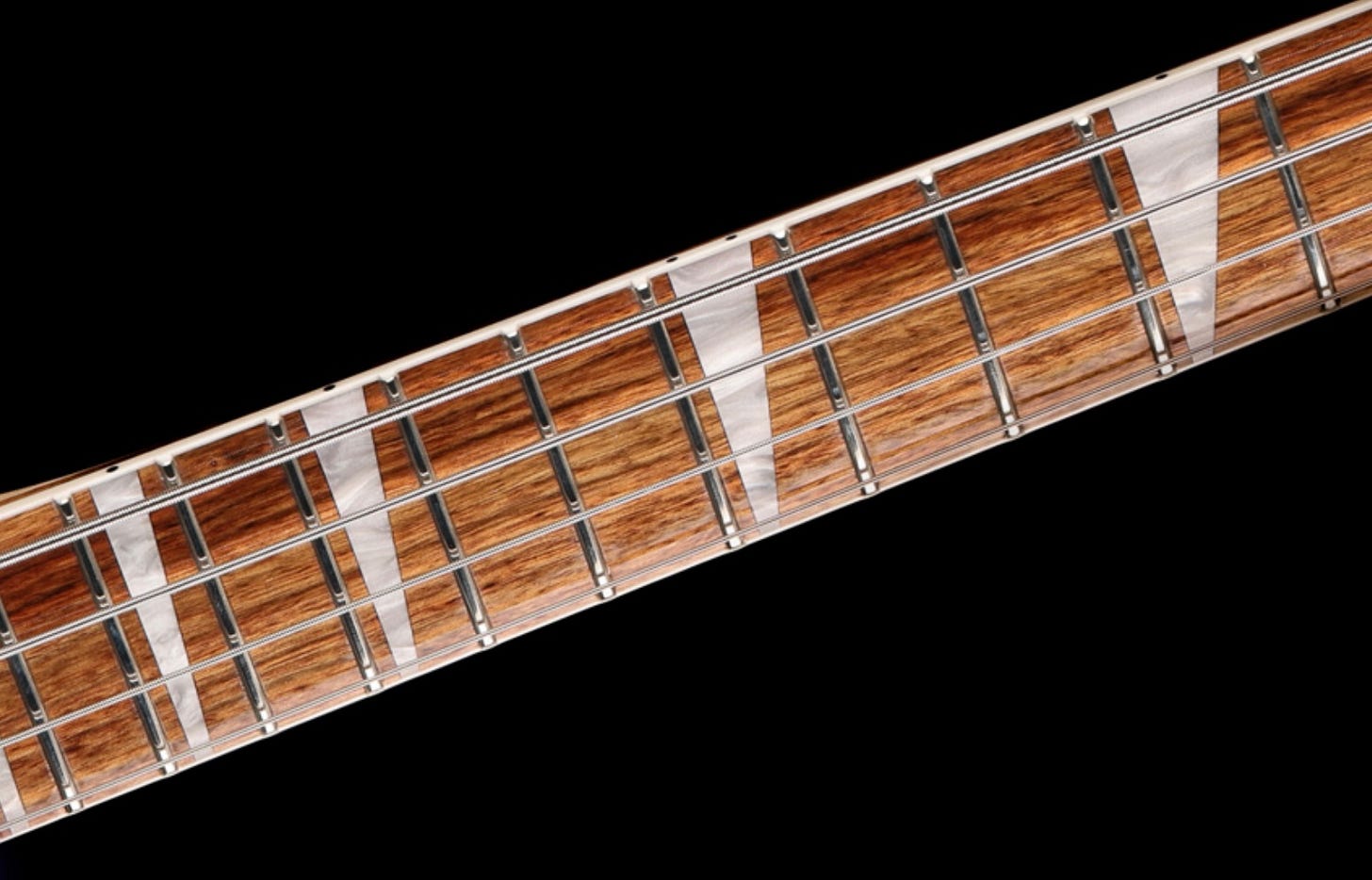

2008 saw the return of full width triangle inlays on all deluxe models, including the 4003. The inset poured resin markers used since 1973 were replaced with full width inlaid pearloid acrylic markers.

But do you want to see something really weird? Here’s something really weird. Despite full width acrylic inlays appearing in January, during the month of February—and only the month of February—all 4003s came with INSET acrylic inlays.

Never a big seller, the 4003FL was officially discontinued with the last batch completed in July.

2009

In October the neck construction changed from one piece to two center seamed pieces. The same happened to all solid-bodied guitars and basses over the course of the year.

2011

There is much debate (and misinformation) about the wood Rickenbacker has used for their fingerboards. While the company has always used the generic “rosewood” terminology, the specific genus and species used has changed over time. Consequently, “bubinga” or “African rosewood” are the terms most commonly used to describe the fairly evenly colored, tightly grained, fairly porous and slightly reddish boards historically used.

In late 2011 that changed to chechen, a Caribbean rosewood. Chechen is browner, has more color variation, a more charactered grain, and a less porous grain, meaning there is much less white grain fill used on the boards—that grain fill being a defining part of the Rickenbacker board “look” in many people’s eyes

2012

A very subtle change was made to the “MADE IN U.S.A.” font on all raised letter truss rod covers. The new font is a little “squarer” and more “compact”.

2014

The 4003W joined the line, with walnut body wings, a maple fingerboard, and a rubbed oil finish. All other features identical to the “standard” 4003.

2015

The 4003S returned to the line. It featured an unbound contoured body, unbound neck with dot position markers, and mono wiring. All other features were identical to the “standard” 4003.

The 4003SW also joined the line, identical to the 4003W apart from walnut body wings, a maple fingerboard, and rubbed oil finish.

When the S models launched in March, they brought with them a slightly redesigned pickguard. As seen below, the new pickguard more closely follows the body lines.

2018

A second version of the 4003S/5 was introduced, purpose built this time with a wider neck, a Schaller 3D bridge, and new triangular pickup “comprised of two blade magnets that angle further out towards the B-string to work at a wider magnetic field, which offers an even deep tone across all 5 strings”. Because the headstock had been lengthened since the first version of the 4003S/5, there was no need to modify the headstock wings to hold the extra tuner.

At the same time the 4003S/5W was launched, featuring walnut body wings, maple fretboard, and a rubbed oil finish.

2019

In June production began on the 4003AC Signature Limited Edition bass. Based on the 4003SW and featuring some polarizing cosmetic elements like the green inlays and double treble pickups, it also featured two major changes that would eventually make their way into the rest of the 4003 line: an improved “V2” bridge, and a single dual-action truss rod.

The V2 bass bridge appeared on all production 4003s in August.

The bridge was designed to address a number of flaws inherent to the original design. To eliminate tail lift, the strings attach to a separate string retainer attached directly to the body. To improve intonation, each string received an individually adjustable roller saddle with a much wider range of movement. And the height on each saddle could now be individually adjusted.

Despite these improvements, some still complain that even decked the saddle height is still too high.

2020

Whether it was a conscious decision or a COVID supply chain issue that just became permanent, the silver topped knobs that had been standard on all core Rickenbacker models since 1965 began phasing out across the entire line. By the end of the year, black “vintage” knobs became standard on all models, including all 4003 variants.

2021

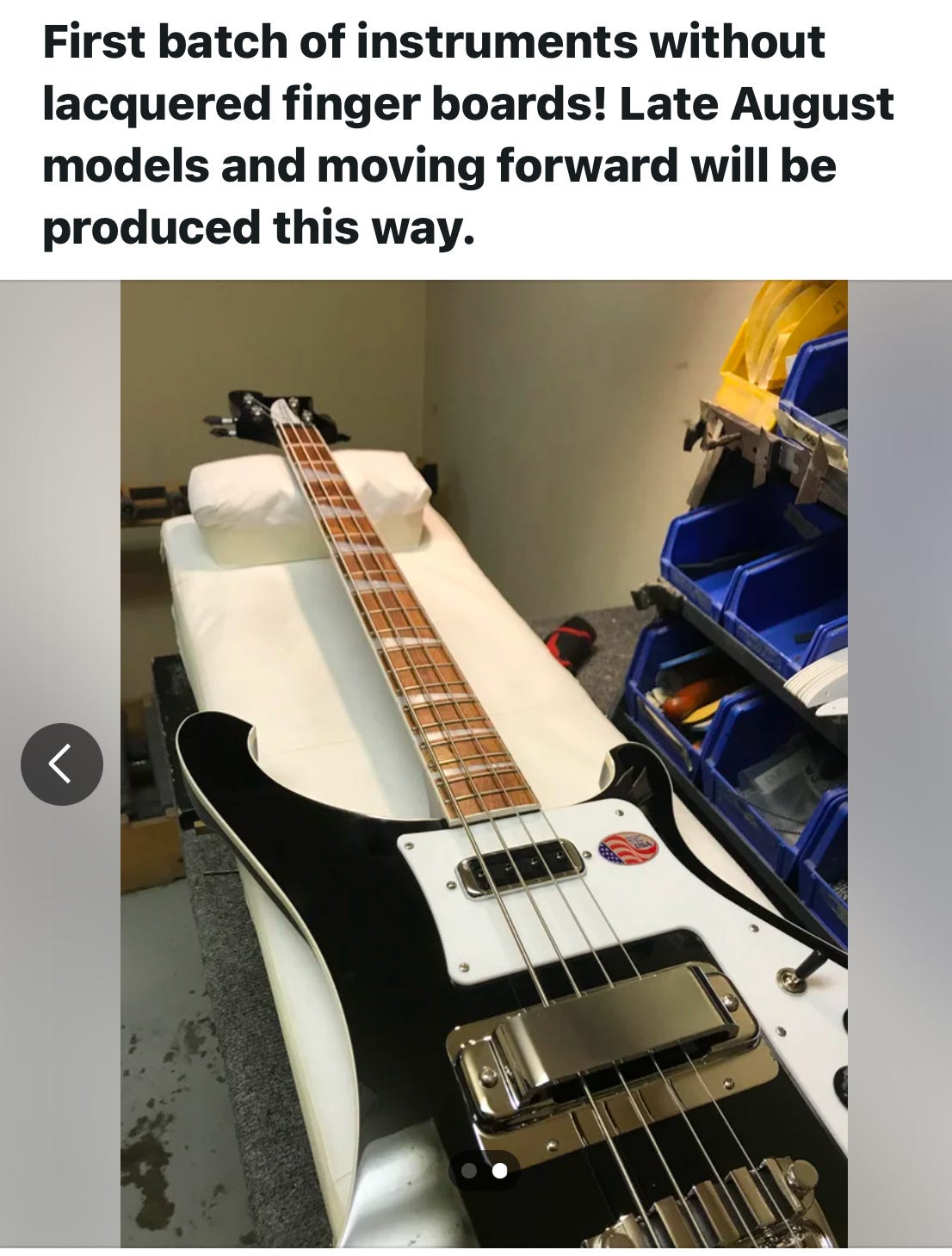

In August a monumental change took place: fingerboards went from being finished to unfinished on all core instruments, including the 4003.

2022

Two significant neck changes occurred in February. First, construction changed from two piece to three piece with the addition of a center walnut “skunk stripe”, harkening back to the 4001. And at the same time, the double single-action truss rods were dropped in favor of a single dual action truss rod as first seen on the 4003AC in 2019. Rickenbacker basses had featured double truss rods since the 1950s, making this truly the end of an era.

Around September Rickenbacker quietly began finishing fingerboards again, ending a brief and unsuccessful experiment.

2023

The change to a single truss rod meant more material could be removed from the neck, and so the profile was reshaped to a shallower “D” profile compared to the previous “C” profile. Average neck depth decreased around 2-2.5mm, drawing multiple comparisons to the prized thin necks of late 60s/early 70s 4001s.

In mid-year the tuner manufacturer changed to Gotoh, but the new tuners are cosmetically identical the Schallers they replaced.

2023 also marked the last year of production for the 4003S/5 V2.

2025

In February Ben Hall announced that the purely cosmetic yet iconic treble pickup cover would be deleted, to be replaced by a new one piece surround with built in thumb rest.

And that’s where we stand as of March, 2025. As new changes appear, I will update accordingly. But despite the many, many changes that the 4003 has seen over the years, it is still instantly recognizable, and still looks and sounds like no other bass on the market.

Fantastic overview of the evolution of Rickenbacker’s most iconic bass!

Curious that you didn’t start a few years previous, as the earliest 4000+1 basses had quite a few variations as well.

(Sand cast aluminum bridge/tailpieces that didn’t lift, 1/2” spacing on the neck toaster were the 2 biggest ones.)